IOT projects

I love interfacing microcontrollers with sensors and actuators, learning new programming languages and designing innovative integrated solutions2023 - RFID

2023 Feb 27 - March 12

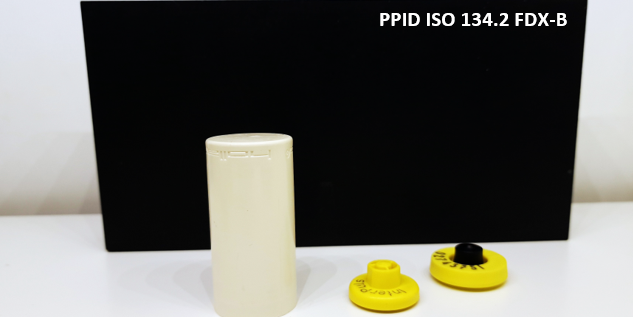

In the last 2 weeks I've been working at a fully independent RFID prototype for animal identification,

equipped with a 134.2 kHz FDX-B transceiver capable of reading and decoding ISO 11784-11785 transponders at a distance between 15cm and 45cm.

The unit autonomously preprocesses all ID operations, special rules can be applied to different applications to correct errors and unpredictable animals behaviour.

The correct responder numbers are then transferred to external servers via WiFI (wired options are also available).

The prototype already integrates an "ID monitor" accessible via multiple client browser (phone, tablet, PC) and the data are instantly logged into local/remote SQL databases,

ready for parlor automation and database integration.

The ID unit is IOT connected and can be programmed to operate:

- as an entrance antenna

- as a per place antenna

- as a carousel antenna

- as a feed robot antenna

- as a counting gate antenna

- as a scale antenna

- etc...

One control unit can manage multiple (wired) transceivers, if required, and its analog/digital pins can be programmed to control traffic/sorting gates, feed stations, vacuum gauges, etc...

2023 March 29 - quick technical test of the prototype

I took the prototype with me today on a farm visit for a first quick technical test in the field, just to check how this small antenna behaves in a real envoironment with different local and remote sources of electromagnetic noise,

and the result exceeded my expectations!

2023 Feb 27 - March 09

at the end of February I took with me on a business trip a small development kit with a compact NFC antenna and in my spare time I started working on a fully independent wrist wearable ID unit,

ready for complex applications and cost-effective ID solutions, even with standalone milking systems.

When a bail tag is detected, the scanner searches for the corresponding animal tag.

When the animal's transponder is also identified and associated, the information is immediately displayed in the ID Monitor and all records are instantly

logged in the database. Identification errors are prefiltered before being passed to the SQL database and corrections are applied before and after.

It is also possible to set a function (parlor side) to automatically release the cluster when a bail is identified (autostart).

This prototype is powered by an old 3.7 V Lipo battery and it works for more than 3 hours with the antenna always activated.

With a few efficiency rules I expect it may reach up to 8-9 hours on a single charge.

I also intend to add a simple user interface, with an autonomous WiFI hotspot for easy startup configuration or standalone operation. On the server side I may build a simple parlor-monitor to display custom alerts from an external software and allow to send instructions back to the database. ...Works in progress..

Web Servers

2018 - System Configurator

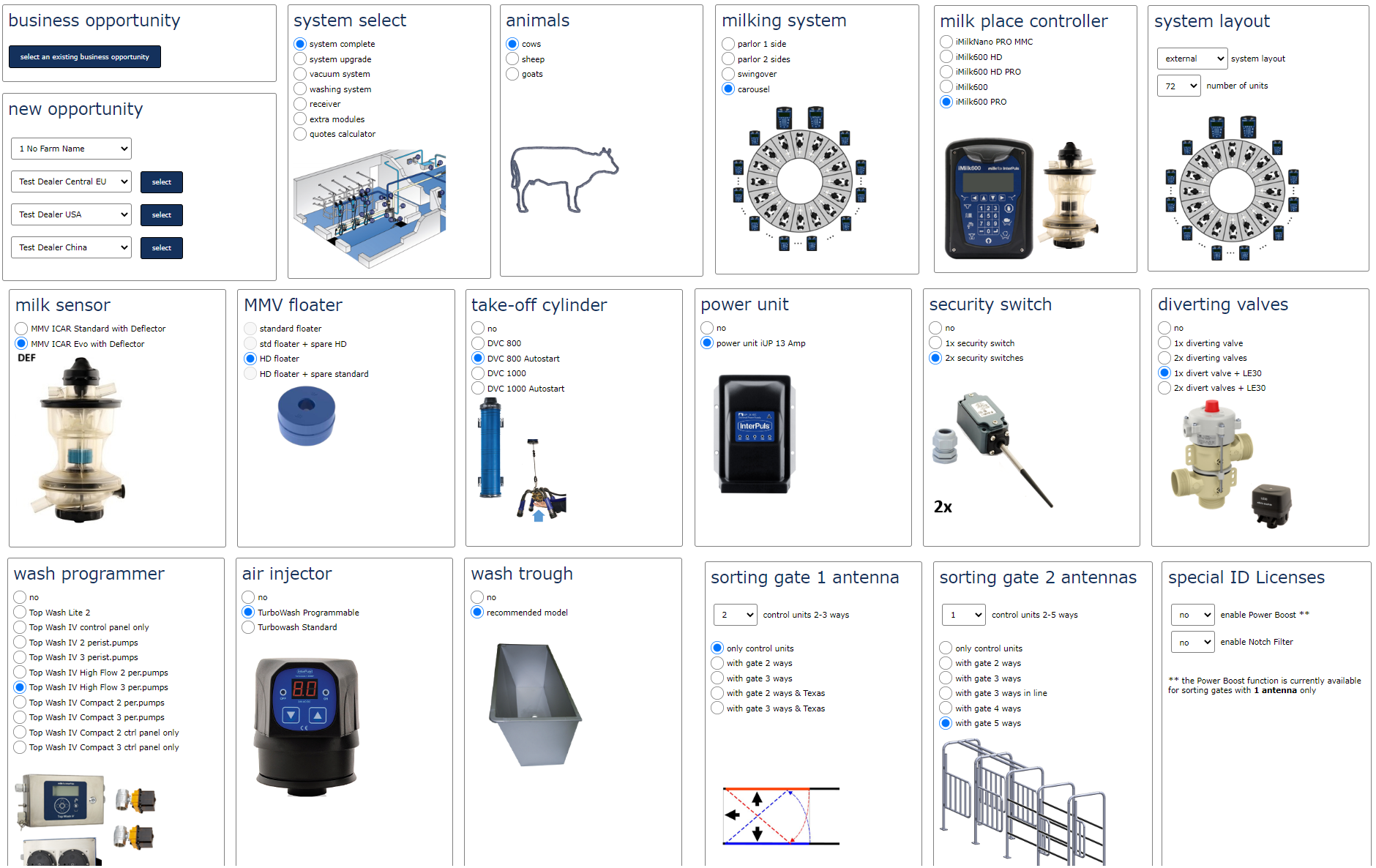

in 2018 I built a web server to support our Sales Team through the configuration of

complex automation systems, up to the printing of a multilingual official quotation document.

The system configurator is linked to the Compamy ERP Systems and to the CRM system and every year generates more than 700 CRM Business Opportunities, including

one or more quotations 💥

(PHP+JS+SQL+CSS-HTML)

2020 - BIG DATA

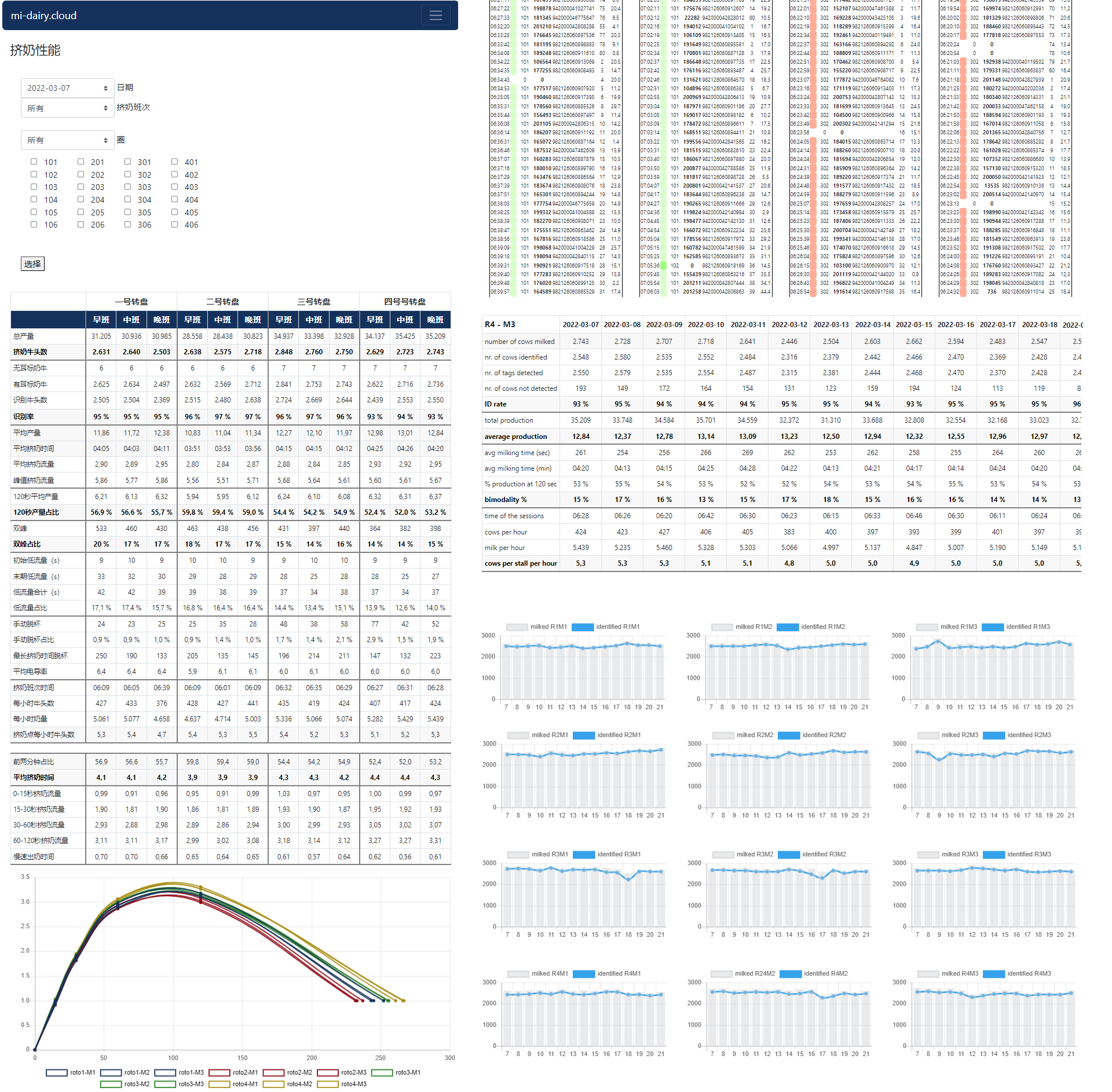

in 2019 we sold a large automation system composed of 4 milking machines, with 320 MPCs (Milking Place Controllers) serving 2 herds with +12k high-genetic cows.

The farm managers required advanced perfomance indicators which they previously downloaded 3 times a day from 4 computers and combined on an Excel file

to compare the performance of the 15 teams that work 24/7 on the 4 machines, over 3 daily shifts.

To respond to this request I built a responsive web server that every 30 minutes uploads data from a remote cloud,

where millions of records are logged in real time by the 320 MPCs.

The server allows to instantly extract 7 pages of statistics, comparing the results of the 4 machines and displaying the trend of the last x days.

Data are also compared by group, by session, by time, etc... and particular importance is given to animals welfare indicators (preparation time, milk ejection curve, etc...).

I also added a custom report page that allows to query data by herd, by group, by period, by machine, by milk-flow (regular, bimodal), by preparation time,

by type of process (automatic, manual, detachment at maximum time, with no-flow), etc...

Finally I added a multilingual help section with specific instructions, a detailed service plan

and 3 pages of diagnostic tools that display the individual performance of each MPC, and higlight those that start to deviate from standard indicators,

enabling easy troubleshooting and the planning of predictive maintenance tasks.

We decided then to extend access to other farms and we currently have +40 connected dairies, with different caracteristics, sizes, types of animals, etc...

🐐

🐑

🐄

🐃

(PHP+JS+SQL+Python+Bootstrap)

2018 - AI Robots

2018 June 12 - welcome Jarvis, our first little AI robot

we had a lot of fun assembling this little robot, programming it as our home assistant and teaching him how to move his 6 servomotors to express emotions and moods, such as happiness, embarrassment, curiosity, sadness, fear, surprise... He's great at interacting with humans. Elisabetta took him to school and he engaged the students in fun and interactive lessons, calling them by name, questioning them on various subjects and commenting their answers with jokes. The beauty of this activity is that it introduces children to the basics of robotics, sparking a curiosity that one day could become a real passion for someone. Now it would be nice to equip him with artificial vision so that he can follow the interlocutors with his eyes, understand when they smile, ract when they greet, etc.... Python stuff for a future project! 😎

2017 - FPV Drones

2017 our first FPV drones

in 2017 we discovered this wonderful hobby, which combines the passion for electronics with the dream of flying. I am now an EASA certified A1/A3 Drone Pilot and we always carry a small FPV drone with us in our backpack, wherever we go 🚀

2013-2014 projects

added wired control through a 3 axis accelerometer and stretch sensors

added ZigBee wireless control - IEEE 802.15.4 WPAN (wireless personal area networks)

RFID system access control

wireless accelerometer - data logger - analysis of z axis to monitor animal's behaviour

wireless accelerometer - logic implemented, prototype and server ready for the field test

2013 - home (made) automation

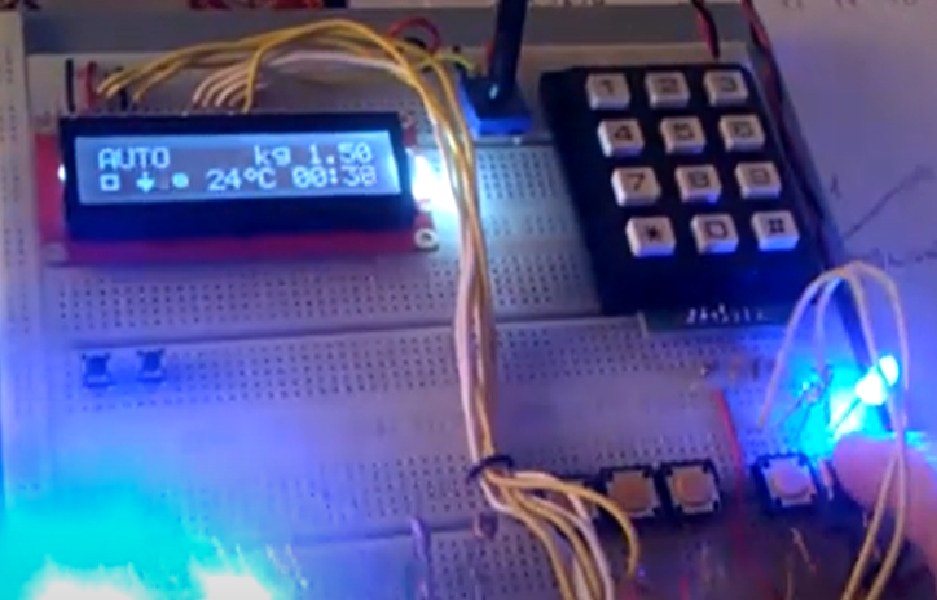

Nov 2013 - web-server on a microcontroller

this was my very first elementary web-server integrated on a simple microcontroller. Thanks to this first experience, one year later I set-up a system of wireless WIO servers to control the air-conditioner, the heater and 3 lights through temperature / umidity / light sensors, with the possibility to adjust the parameters and send controls from a custom Web App and a few HTTP shortucut icons on the desktop of the phone. The air conditioner was controlled with infrared codes hacked from the remote controller, while lights and heater were activated by wireless micro-switches. This system has been running 24/7 at home for more than 7 years and has been replaced only with the arrival of a Netatmo thermostat and a new air conditioner with WiFi integration.

2013 - designing specs for a new MPC

Dec 2012 - Jan 2013 - iMilk600 - exploring prototype

Back in 2012, I was Product Manager Automation at the company I work for and intended to convince the owners to make a BIG investment on a new product that would totally change our business, so I decided to build a prototype on an Arduino Mega microcontroller before writing the specs for the project.

The entire research took all my Christmas holidays that year, but allowed to create an extensive document where all functions and processes were tested in real life before being explained in a structured form. Our Engineers and external suppliers have then transformed this project into a successful product, that 10 years later is still driving the business of our Automation Range

2013 - pacman

learning to code in Javascript

I really needed to improve my Javascript skills so in 2013 I decided to follow some tutorials and I made a couple of pacman demos.

To move pacman, you can use the 4 arrows on the PC keyboard and zoom-out your browser to display the complete interface.

I'm still bad at JS 😅, but it was quite fun bulding a demo of a game that I played so many times when I was a kid.

This is a quick JS startup guide that I made in that occasion.